Easy to Create: Digital Plant Pre Start Checklist Template

Creating a Plant Pre Start Checklist involves generating a complete list of inspections, potential issues, and maintenance needs before starting work on a job site. Additionally, it is a significant component for all industries where accuracy and reliability are essential. With Record TIME's plant pre start checklist template, you can ensure that the equipment is safe, effective, and compliant helping to reduce the risk of accidents and operational failures.

Ensuring the smooth operation of plants is vital for maximising efficiency and productivity in any industry. Plant operators and managers can effectively address potential safety risks, equipment problems, and environmental issues by systematically reviewing key aspects of the plants. This proactive approach not only ensures the safety of the employees but also improves operational efficiency and minimises downtime. To improve plant care and maintenance in your industry, invest in the implementation of a thorough plant pre start checklist template.

Benefits of Using a Plant Pre Start Checklist Template

Designing a plant pre start checklists for equipment like forklifts, vehicles, excavators, or trucks is important for safety and regular maintenance. With Record TIME, it’s so easy to create any pre start checklist, you can use templates available in the dashboard or simply create one by yourself using drag and drop technique. Additionally, it uses a digital docketing approach to create these pre start checks, which are shareable through one click.

How to Conduct Pre Start Inspection for Plants with Record TIME?

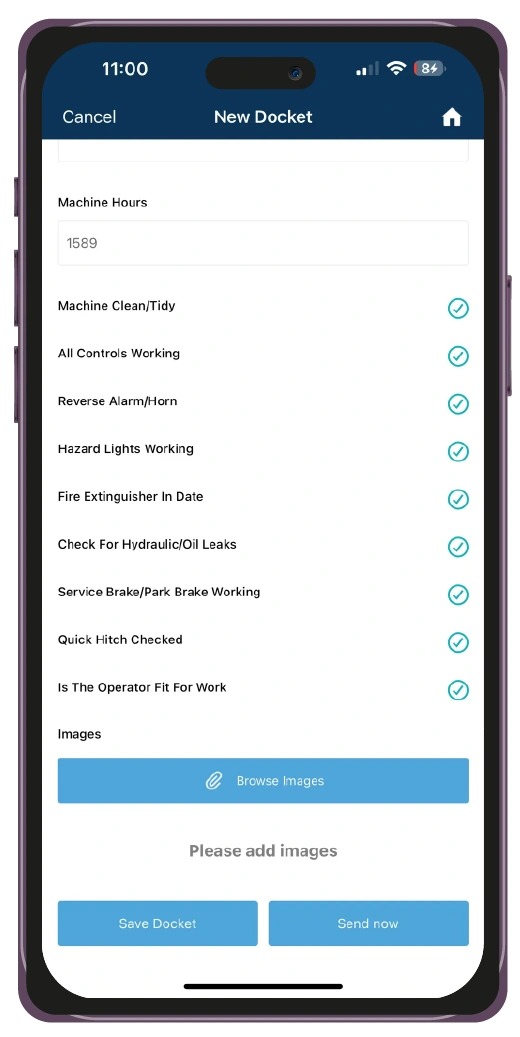

Today we will design a basic pre start checklist template. The checklist will look like the following:

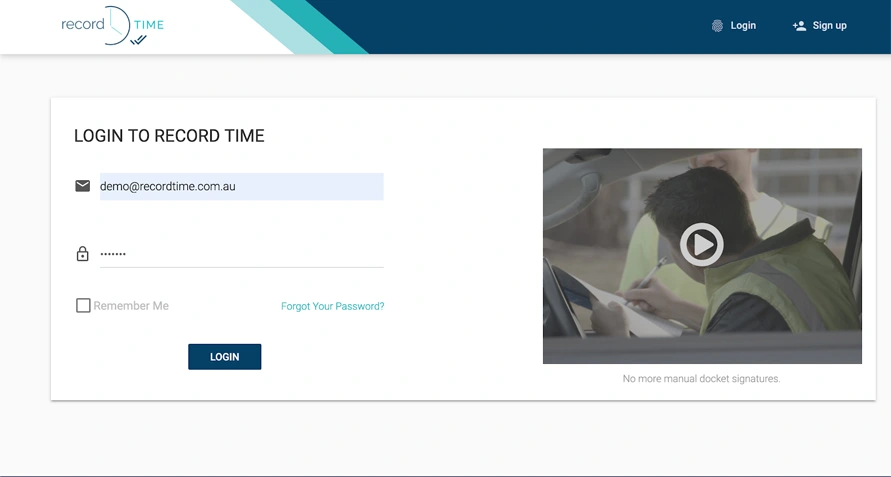

1. Log on to Record TIME using your details:

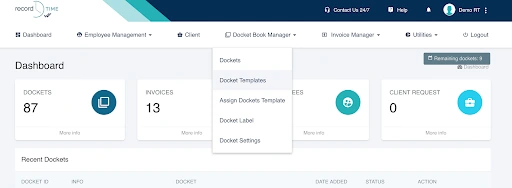

2. Click Docket Book Manager and then click Docket Templates:

3. Click Add new

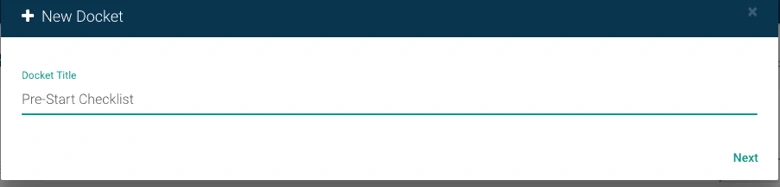

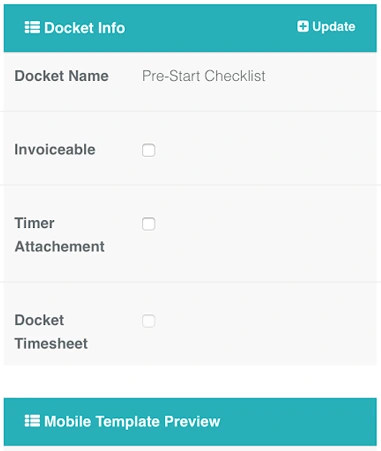

4. Fill in the title “Pre Start Checklist” or whatever you would like to name this template:

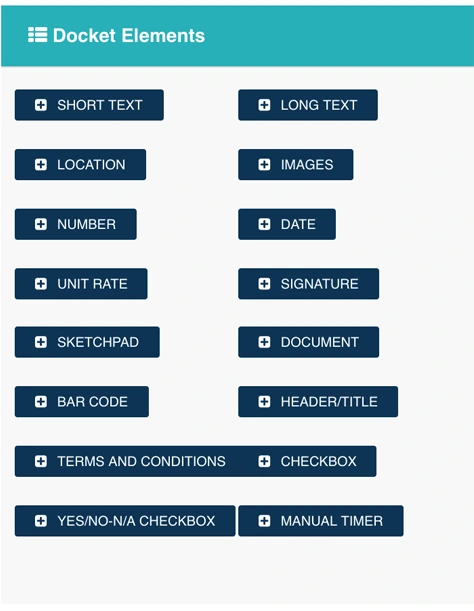

5. In The screen below the first box (1) represents the docket book. These include items like short text, long text date, and so on. The Box number (2), has some parameters, tick invoiceable if you want to use these dockets in invoices.

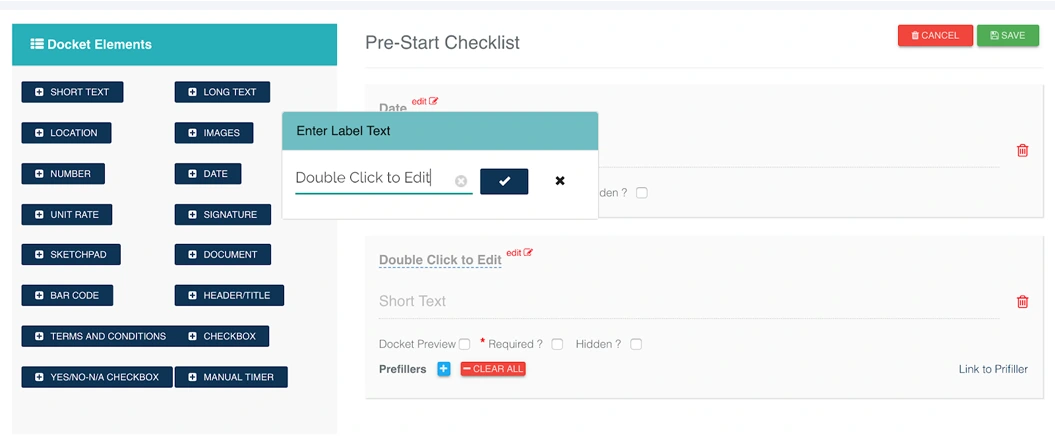

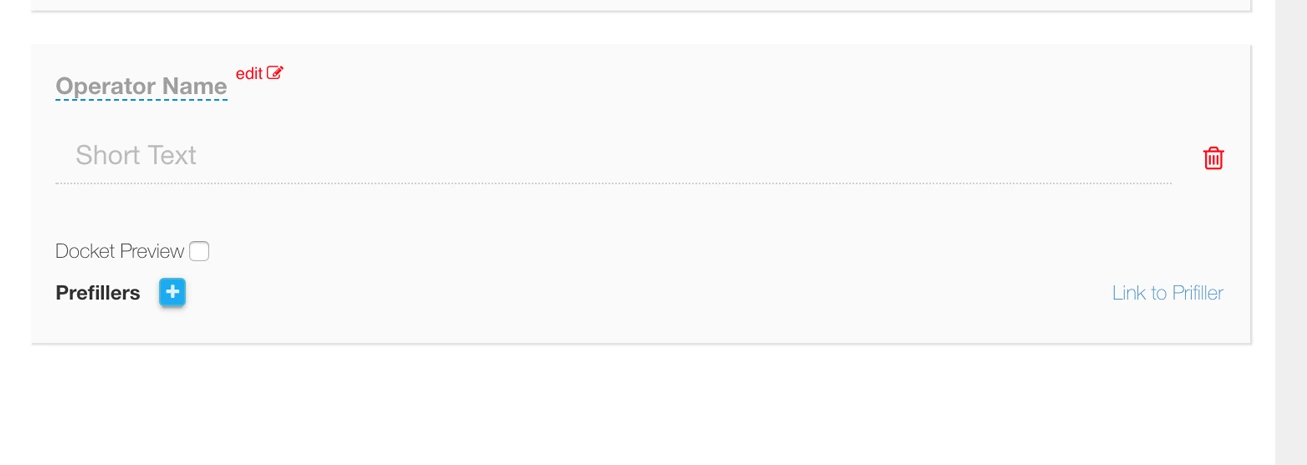

6. Click Short Text on Box 1 and the design screen should now look like:

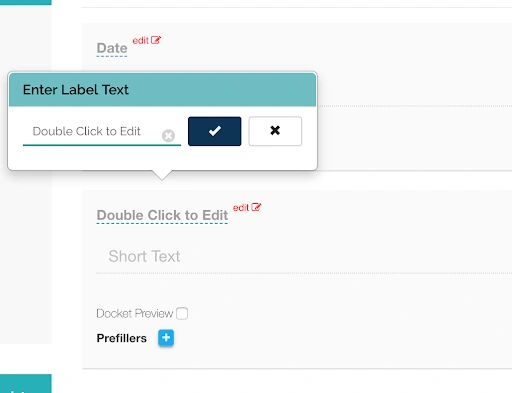

Double click the text to edit the label text:

Given that, the field should now look like this.

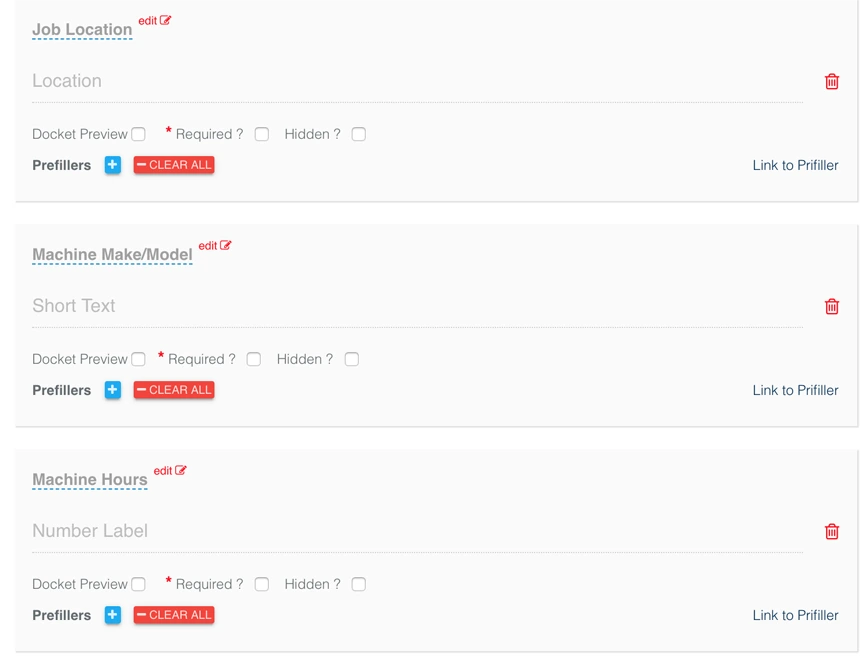

7. Add a location field, a short text field, and a number field and change their labels to Job location and Machine Model and Working Hours respectively. At this time, your screen looks like this:

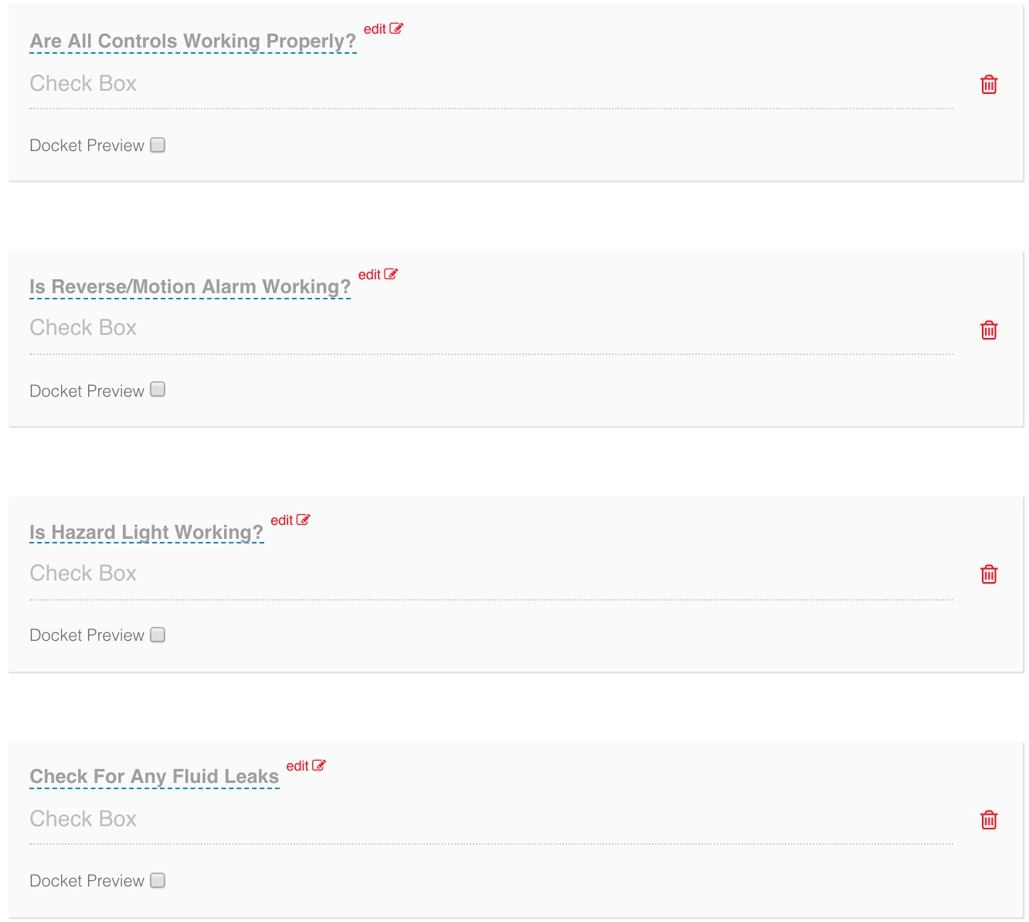

8. We will now add some checkbox fields from box (1) as shown. The items will be:

- Are all controls working properly?

- Is Reverse/Motion Alarm working?

- Is Hazard light working?

- Check for any fluid leaks

These are the checkbox fields that are added, they look similar on your screen.

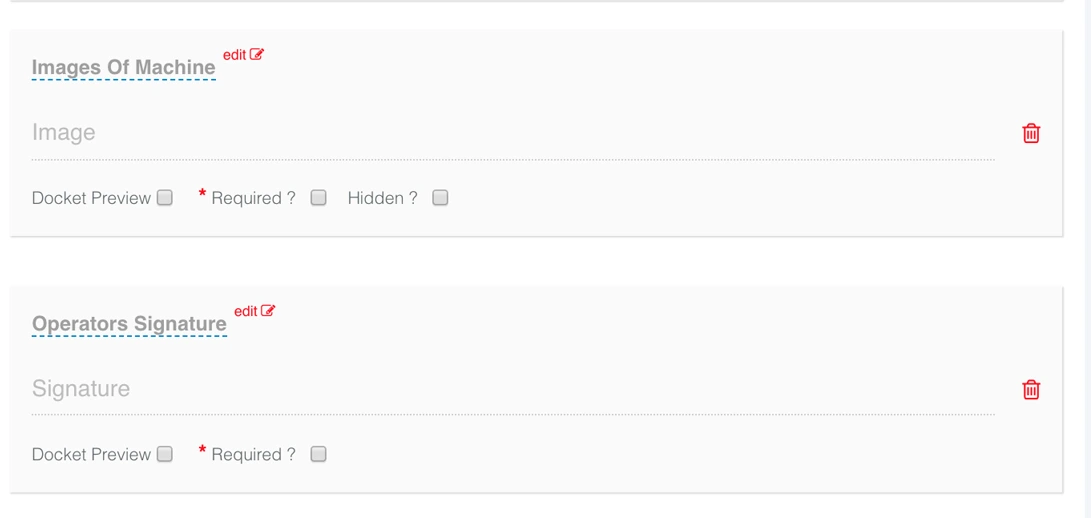

9. Our pre start checklist wouldn't be complete without notes, images of the machine, and the operator's electronic signature. Following, go ahead and add a short text field called “Notes”, an image field and call it “Images of Machine” and a signature field called “Operators Signature”. The screen now:

10. And there you have it, not only have you successfully created a basic plant pre start checklist but you can also make this pre start check more comprehensive by adding other elements.